Research in mechanical engineering (6011-M)

The course takes place in the 2nd year of the master’s degree study (Level 2), field of study: DESIGN and DEVELOPMENT of PRODUCTS and MECHANICS of MATERIALS, SYSTEMS and PROCESSES. It includes 90 hours of lectures and 90 hours of lab work, together accounting for 15 credit points (ECTS).

The Chair of Modelling in Engineering Sciences and Medicine contributes to the course in the following interdisciplinary research fields:

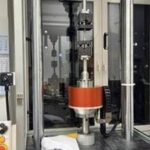

1. Material characterization and development of material models,

2. Special development know-how,

3. Biomechanics and

4. Traffic safety and information technology.

The main objective of this course is to introduce the students to the aforementioned research fields and the interconnection between them. The course enables the students to do research in a selected research field and present their ideas and findings in their master’s thesis. Individual fields of research are complementary and have synergistic effects between the industrial, academic and research environment and public institutions.

The lessons take place in a laboratory where the students can participate in the development and application of new skills and methods of numerical evaluation, analyses and measurements of technical systems in various fields of engineering sciences and medicine (design and optimisation of structures and objects to improve traffic safety, development of models to predict the stress-strain state and lifetime of objects made from advanced materials and structures, soft tissue characterisation by taking into account the impact of the muscle response on their injuries, development of human-body models, blast and ballistic protection, vehicle kinematics and dynamics, traffic infrastructure, traffic information technology, measurements and validation).

Geometrical product specification (6029-M)

The course takes place in the 1st year of the master’s degree study (Level 2), field of study: DESIGN and DEVELOPMENT of PRODUCTS and MECHANICS of MATERIALS, SYSTEMS and PROCESSES. It includes 30 hours of lectures and 30 hours of lab work, together accounting for 5 credit points (ECTS).

The students of the Faculty of Mechanical Engineering can access all materials and additional information on the course in the online classroom of the course Geometric product specification.

In recent years, the International Organization for Standardization (ISO) has become a leading international standard-setting body in the fields of geometrical product specification as well as technical product documentation. The new ISO standards (the amendments and supplements made after year 2009 are particularly important) along with the updated old standards are increasingly becoming a complete tool that based on clearly identified concepts and rules enables a systematic and detailed description of all geometric requirements that are to be met in the manufacturing process in order to achieve the required functionality and ensure the composability and substitutability of assembly elements. Although this is favourable for engineers, there is also a disadvantage. Based on these standards, the terminology and symbols used on drawings will be altered and completed (increased) in some parts, which will require substantial understanding of the new concepts as well as fundamental and implemented rules. In some cases, tolerance analysis will become more complex and challenging. This course covers the following topics:

- Introduction and basic definitions,

- Introduction to GPS on virtual (3D) models and technical drawings (2D),

- Linear and angular dimensions and tolerances, fits,

- State of surfaces and corners,

- Geometric dimensioning and tolerancing (GD&T),

- GD&T – datum and datum systems (references and reference systems),

- Material conditions of GD&T, meaning and application,

- Geometric tolerances (GT) of position and profile,

- General GT, verification methods and basics of tolerance analysis (TA),

- Statistical tolerances and statistical process control (SPC),

- Tolerance analyses – systematic approach,

- Import of GPS to 3D virtual models and data transmission into technical documentation (2D),

- Standard file format and software for transmission and reading of GPS data applied in the manufacturing process (3D format),

- Systems of managing technical documentation in the development (design) process as well as other information management systems and quality criteria/systems.

Mechanisms analysis and synthesis (6043-M)

The course takes place in the 2nd year of the master’s degree study (Level 2), field of study DESIGN and DEVELOPMENT of PRODUCTS and MECHANICS of MATERIALS, SYSTEMS and PROCESSES. It includes 30 hours of lectures and 30 hours of lab work, together accounting for 4 credit points (ECTS).

The students of the Faculty of Mechanical Engineering can access all materials and additional information on the course in the online classroom of the course Mechanisms.

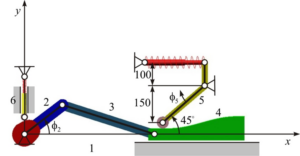

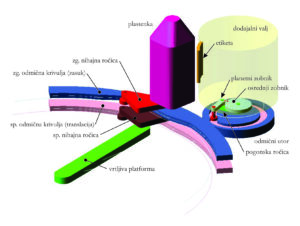

The course covers analysis and synthesis of mechanisms whereby the students are introduced to basic terminology of the theory of mechanisms, principles of operation and implementation of the most common mechanism types, they become familiar with the theoretical basis for efficient analysis and design of mechanisms as well as the use of purpose-developed software tools. The lectures first cover the theory of mechanisms with the emphasis on the definition and function of mechanisms or a system of constrained bodies (structure, mechanism, machine), kinematic chains and joints, degrees of freedom, planar and spatial motion, inversions as well as classification of mechanisms and principles of their operation and implementation. The course also covers the kinematics of mechanisms, instantaneous centre of zero velocity and instantaneous centre of zero acceleration, theorems in the kinematics of mechanisms, kinetics of the mechanisms (loads and energy transmission), analysis of operation for basic mechanism types (four-bar, crank-slider), cam-follower mechanisms (implementation, function, analysis of operation and design requirements), the design process and synthesis of basic-type mechanisms and mechanisms with elastic elements. The lab work, however, is focused on the application of numeric simulations for the analysis of mechanism operation. The students gain the knowledge to solve average problems in the design, analysis and optimisation of mechanisms.

The covered topics are presented in the textbook entitled Analiza in sinteza mehanizmov (Mechanisms analysis and synthesis).